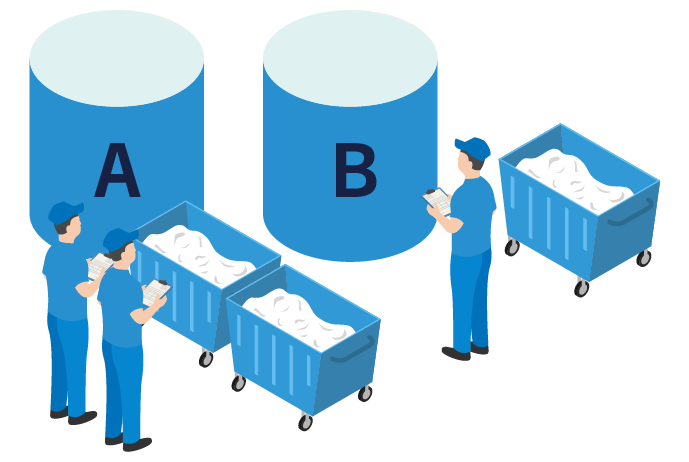

There was a big difference in operating occupancy rates between the two kilns used for the rough denim process.

※Washing kilns A and B are the same type of kiln but different sizes.

Washing kilns A :80%

Washing kilns B:30%

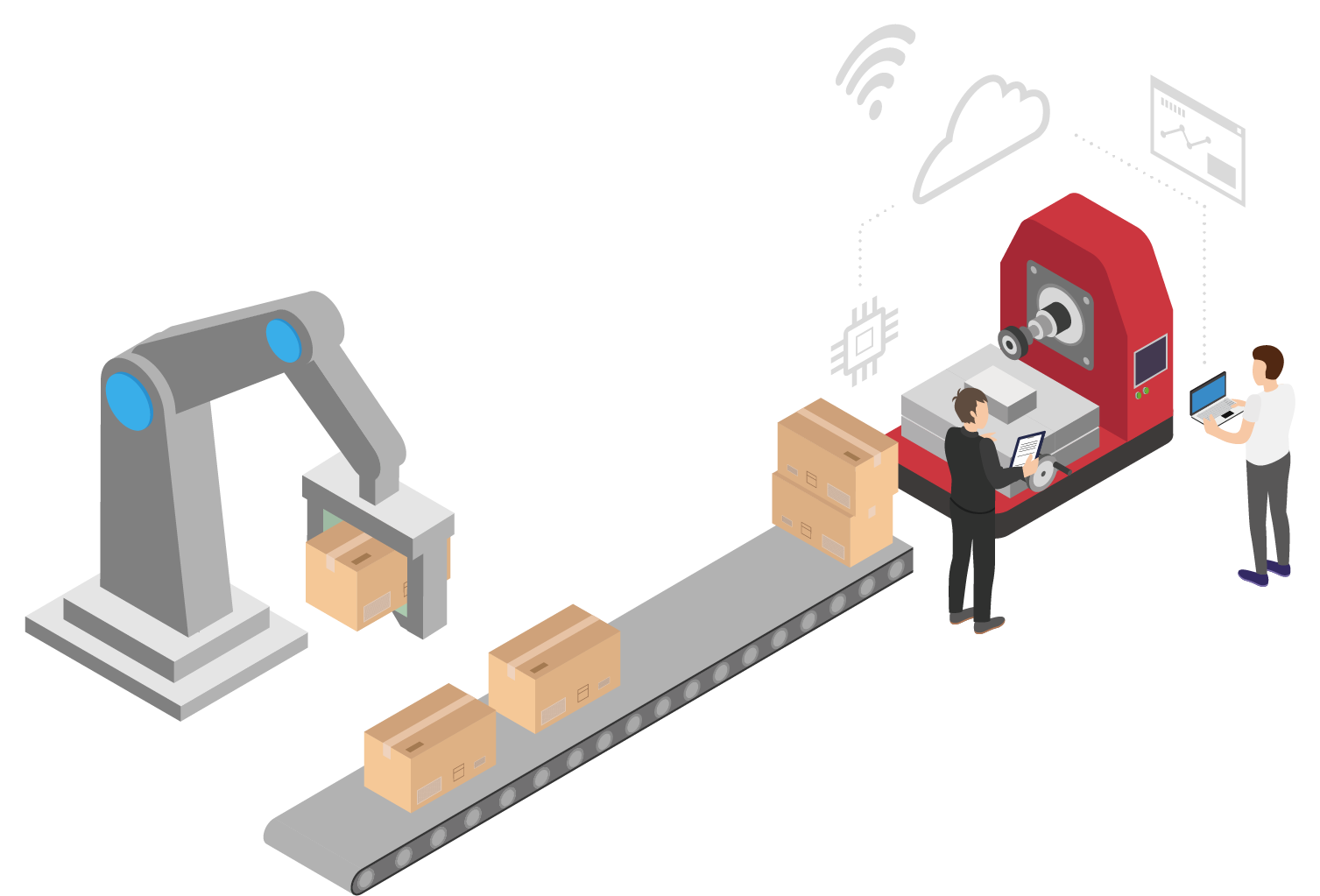

For those who want to introduce DX technology or have already introduced it but have not been able to utilize it.

Pruductivity

Improvement

Solution

Pruductivity Improvement Solution

FRICS Fab offers various services for realizing DX every corner, such as automation of production lines.

Solution Menu

Equipment Operation

Monitoring System

Visualize the relationship between facility operation and operations by extracting data as a first step to optimize the utilization rate.

Automatic Measurement

Inspection System

AI image recognition enables automatic measurement inspections that require human resources.

Plant Simulator

We propose improvements by digitally visualizing the movements of people, objects, and machines, and by constructing a digital twin of the manufacturing plant.

Robot Solution

Robots are introduced to manufacturing plants to improve plant production efficiency.

Case Example

Here are some of the changes that have occurred in control panel manufacturing.

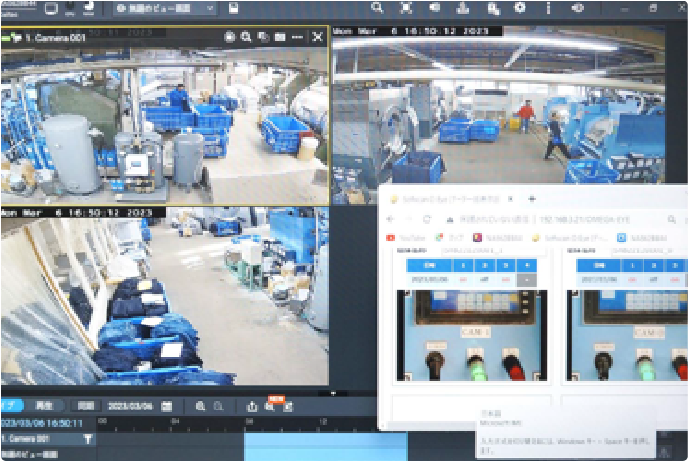

- Own-brand denim manufacturing

Soja Caitac Factory, CAITAC INTERNATIONAL, INC. Discover bias in machine operating occupancy rates through video analysis

Improve operational efficiency

Unbalanced operating occupacy rate

Improve operating occupancy rate differentials

By clearly presenting the data, the difference in the usage rate of washing kilns A and B improved.

We were able to numerically identify issues that were not visible while the on-site staff was working hard.

- Control panel manufacturing

TOYODENSO Co., Ltd. Increased productivity and

35.6% waste reduction

Tools are shared.

Video analysis of work revealed that sharing tools results in wasted movements.

1.Move to pick up and return the tool.

2.Wait time while other workers are using the tool.

Tools are provided for each worker.

Many small and medium-sized companies share expensive tools, but video digitized the craftsman’s movements, and the reduction of this move and wait time could be compared to the capital investment.

By providing a tool for each person, we succeeded in reducing 35.6% of unnecessary movements in some tasks.

- Control panel manufacturing

TOYODENSO Co., Ltd. Discovering craftsmanship and clarifying work

Everyone does the same work.

We categorized difficult tasks that can only be done by craftsmen and tasks that can be done by robots or new workers, and clarified the appropriate person in charge of the tasks.

Determining the wiring route of a control panel is actually a very difficult “craftsmanship” that is difficult for designers and others to do.

Right person in the right place.

“Right person in the right place.” means that we have reviewed the distribution of work so that craftsmen can focus on high value-added work by placing the right person in the right place.